Manufacturing industries have always strived for operational excellence, seeking ways to streamline their processes, enhance productivity, and stay ahead in the competitive market. In this era of digital transformation, implementing an erp manufacturing software solution has become a game-changer for businesses. But what exactly is an ERP Manufacturing Software Solution, and why is it so important for manufacturers?

Definition of ERP Manufacturing Software Solution

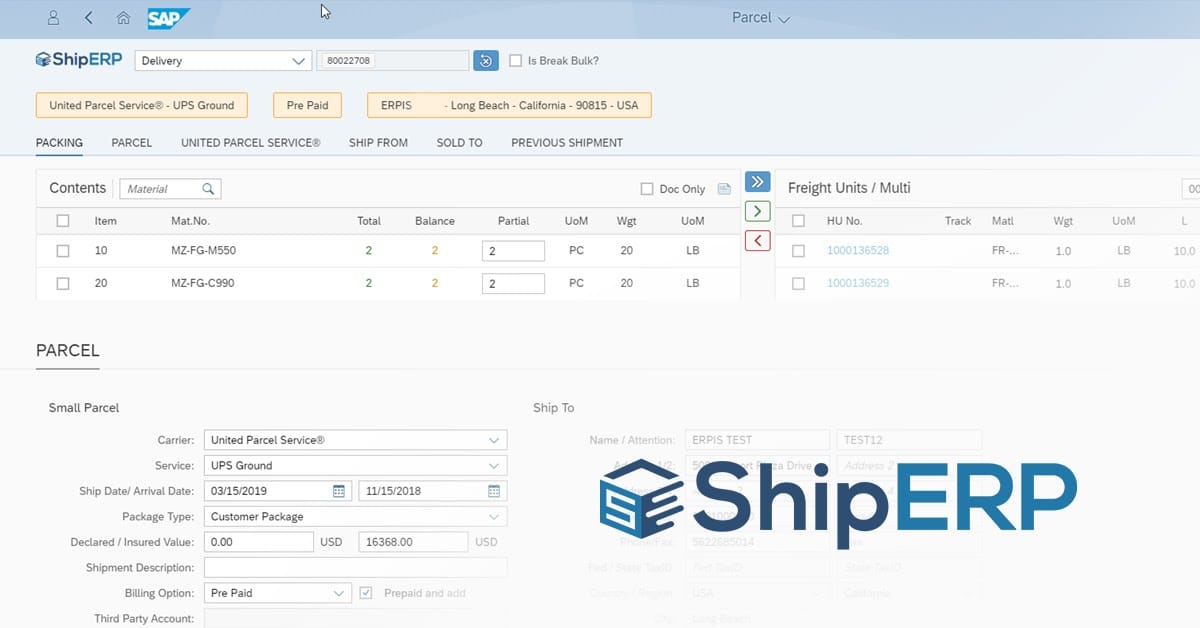

An ERP Manufacturing Software Solution refers to a comprehensive system that integrates various business processes within a manufacturing company. It enables seamless coordination and automation of tasks, ranging from procurement and inventory management to production planning and customer relationship management. By providing a centralized platform for data management, real-time analysis, and reporting, ERP software empowers manufacturers to make informed decisions and streamline their operations efficiently.

Importance of implementing ERP software in manufacturing industries

In today’s fast-paced manufacturing landscape, staying competitive requires manufacturers to optimize their processes and adapt to changing market dynamics. ERP Manufacturing Software Solution plays a pivotal role in achieving these goals. By providing a holistic view of the entire manufacturing process, ERP software enhances operational efficiency, reduces manual errors, and improves resource utilization.

Overview of the benefits and features of ERP manufacturing software solution

ERP Manufacturing Software Solution offers a wide range of benefits and features tailored to meet the specific needs of the manufacturing industry. Some key advantages include:

Streamlining production processes: ERP software enables manufacturers to optimize their production schedules, minimize downtime, and ensure efficient resource allocation. By automating workflows, it eliminates manual bottlenecks and accelerates the production cycle.

Inventory management and control: With real-time visibility into inventory levels, ERP software enables manufacturers to optimize their stock levels, reduce carrying costs, and avoid stockouts or overstocks. It also facilitates better demand forecasting and enhances supply chain management.

Supply chain management: ERP software streamlines the entire supply chain, from procurement and order management to logistics and delivery. It enables manufacturers to collaborate seamlessly with suppliers, manage vendor relationships effectively, and ensure timely delivery of products.

Quality control and assurance: ERP software incorporates quality control measures throughout the manufacturing process, enabling manufacturers to monitor product quality, track defects, and ensure compliance with industry standards. This improves customer satisfaction and reduces the risk of recalls or product failures.

Real-time data analysis and reporting: ERP software provides manufacturers with real-time access to critical data, enabling them to make data-driven decisions. Advanced analytics and reporting capabilities help identify trends, measure performance, and identify areas for improvement.

In the next section, we will delve deeper into the key features of ERP Manufacturing Software Solution, exploring how it revolutionizes the manufacturing landscape. Buckle up as we unlock the potential of ERP software and uncover its immense value for manufacturers worldwide.

Understanding the Key Features of ERP Manufacturing Software Solution

In the fast-paced manufacturing industry, efficiency and effectiveness are paramount. This is where ERP Manufacturing Software Solution steps in, offering a plethora of key features to optimize processes and drive productivity. Let’s explore some of the critical functionalities that make ERP software an indispensable tool for manufacturers.

Streamlining production processes and improving efficiency

One of the primary objectives of ERP Manufacturing Software Solution is to streamline production processes, reducing manual efforts and optimizing resource allocation. By automating workflows and providing real-time visibility into production schedules, manufacturers can eliminate bottlenecks, increase throughput, and enhance overall efficiency. ERP software enables seamless coordination between different departments, ensuring smooth collaboration and minimizing delays.

Inventory management and control

Keeping inventory levels in check is crucial for manufacturers to avoid stockouts or excess stock, both of which can lead to significant financial losses. ERP software provides robust inventory management capabilities, enabling manufacturers to track inventory levels in real-time. With accurate data on hand, manufacturers can make informed decisions about procurement, optimize stock levels, and ensure timely availability of materials. This helps reduce carrying costs, improve cash flow, and enhance customer satisfaction.

Supply chain management

Effective supply chain management is essential to ensure a seamless flow of materials, components, and finished products. ERP Manufacturing Software Solution integrates supply chain management functionalities, allowing manufacturers to collaborate with suppliers, manage purchase orders, and track deliveries. With real-time visibility into the supply chain, manufacturers can identify potential bottlenecks, optimize lead times, and minimize disruptions. This results in improved supplier relationships, reduced risks, and enhanced customer service.

Quality control and assurance

Maintaining high-quality standards is crucial for manufacturers to uphold their reputation and meet customer expectations. ERP software incorporates robust quality control and assurance features, enabling manufacturers to monitor and manage product quality at every stage of the production process. From capturing quality data, conducting inspections, to tracking and resolving issues, ERP software helps manufacturers ensure compliance with industry standards, reduce defects, and enhance overall product quality.

Real-time data analysis and reporting

Data is the backbone of informed decision-making. ERP Manufacturing Software Solution provides manufacturers with real-time access to critical data, empowering them to make data-driven decisions. Advanced analytics and reporting capabilities allow manufacturers to gain valuable insights into production performance, identify trends, and detect areas for improvement. With accurate and up-to-date information at their fingertips, manufacturers can respond swiftly to changing market conditions and optimize their operations effectively.

With a comprehensive understanding of these key features, manufacturers can harness the power of ERP Manufacturing Software Solution to drive operational excellence, achieve cost savings, and gain a competitive edge. In the next section, we will delve into the factors to consider when choosing an ERP software solution that aligns with your business needs and goals. Let’s embark on this journey towards finding the perfect ERP solution for your manufacturing business.

Factors to Consider When Choosing an ERP Manufacturing Software Solution

Selecting the right ERP Manufacturing Software Solution is a critical decision that can significantly impact the success of your manufacturing operations. With numerous options available in the market, it’s crucial to evaluate various factors to ensure you make an informed choice. Here are some key considerations when choosing an ERP solution for your manufacturing business:

Scalability and Customization Options

As your manufacturing business grows, so does the complexity of your operations. It’s important to choose an ERP solution that can scale alongside your business needs. Look for software that offers flexible customization options, allowing you to tailor the system to fit your unique manufacturing processes. A scalable and customizable ERP solution ensures that it can adapt to your evolving requirements without compromising efficiency or productivity.

Integration Capabilities with Existing Systems

Manufacturing businesses often have existing systems and technologies in place that are critical to their operations. When selecting an ERP software solution, it’s essential to consider its integration capabilities with your current systems. Seamless integration ensures smooth data flow across different departments and eliminates the need for manual data entry or duplicate records. Look for ERP software that offers robust integration features to ensure compatibility with your existing infrastructure.

User-Friendly Interface and Ease of Use

To maximize the benefits of an ERP solution, it’s crucial that your employees can easily navigate and utilize the software. Look for an ERP solution with a user-friendly interface that requires minimal training for your staff to operate effectively. Intuitive navigation, clear workflows, and easy access to information are key factors to consider when evaluating the user-friendliness of the software.

Vendor Reputation and Customer Support

Choosing an ERP software solution is not just about the software itself; it’s also about the vendor behind it. Research the reputation and track record of the ERP software vendor. Look for customer reviews, testimonials, and case studies to gauge their credibility and reliability. Additionally, consider the level of customer support provided by the vendor. Reliable support ensures that you have assistance whenever you encounter technical issues or need guidance during the implementation and usage of the ERP software.

Cost-Effectiveness and Return on Investment

While cost should not be the sole determining factor, it’s essential to evaluate the cost-effectiveness and return on investment (ROI) of the ERP software solution. Consider the total cost of ownership, including licensing fees, implementation costs, and ongoing maintenance expenses. Assess the potential benefits and efficiencies the ERP software can bring to your manufacturing operations, and weigh them against the initial and ongoing costs. A well-planned ROI analysis will help you determine the financial viability and long-term benefits of the ERP solution.

By carefully considering these factors, you can make an informed decision when selecting an ERP Manufacturing Software Solution that aligns with your manufacturing business needs and sets you up for success. In the next section, we will explore real-life case studies of successful ERP implementations in manufacturing, showcasing the tangible benefits and outcomes achieved by businesses that embraced this transformative technology.

Case Studies: Successful Implementation of ERP Manufacturing Software Solution

In the realm of manufacturing, success stories often speak louder than promises. Let’s explore some real-life case studies that demonstrate the transformative power of ERP Manufacturing Software Solutions. These companies have embraced ERP software and reaped remarkable benefits, showcasing the potential it holds for the manufacturing industry.

Company A: Streamlining Operations for Enhanced Productivity

Company A, a leading automotive manufacturer, faced challenges with disparate systems and manual processes that hindered their operational efficiency. By implementing an ERP Manufacturing Software Solution, they were able to streamline their operations and achieve remarkable results. The ERP software facilitated end-to-end automation of their production processes, from procurement to delivery. As a result, they experienced a significant increase in productivity, with reduced lead times and improved resource utilization. The real-time visibility into their supply chain allowed them to proactively manage inventory levels, resulting in cost savings and optimized production schedules. Moreover, the integrated quality control module helped them ensure stringent quality standards, leading to improved customer satisfaction and loyalty.

Company B: Overcoming Complex Challenges with ERP Software

Company B, a global electronics manufacturer, faced complex challenges due to their extensive product portfolio and intricate supply chain. They struggled with inventory management, order tracking, and meeting customer demands efficiently. By implementing an ERP Manufacturing Software Solution, they were able to overcome these hurdles and achieve operational excellence. The ERP software provided them with a centralized platform to manage their diverse product lines, track orders, and optimize inventory levels across multiple locations. They experienced reduced lead times, improved order accuracy, and better customer service. The real-time data analytics and reporting capabilities helped them identify trends and make data-driven decisions, resulting in cost savings and improved profitability.

These case studies highlight the tangible benefits of implementing an ERP Manufacturing Software Solution. From increased productivity and reduced costs to improved customer satisfaction, ERP software has proven to be a game-changer for manufacturing companies worldwide. The challenges faced by these companies were resolved through the implementation of ERP software, paving the way for enhanced efficiency, streamlined processes, and sustainable growth.

In the next section, we will explore the best practices for implementing an ERP Manufacturing Software Solution. Join me as we uncover the key strategies to ensure a successful ERP implementation and maximize the benefits it offers.

Best Practices for Implementing ERP Manufacturing Software Solution

Implementing an ERP Manufacturing Software Solution is a significant undertaking for any manufacturing company. To ensure a smooth transition and maximize the benefits of ERP software, it is essential to follow best practices throughout the implementation process. Here are some key steps to consider:

Developing a comprehensive implementation plan

Before diving into ERP software implementation, it is crucial to develop a well-defined implementation plan. This plan should outline the specific goals, timeline, and resource allocation for the project. By clearly defining roles and responsibilities, setting realistic expectations, and establishing milestones, you can ensure a structured approach to implementation.

Ensuring employee training and support

Successful ERP implementation heavily relies on the preparedness and acceptance of your workforce. Providing comprehensive training to employees on how to use the ERP system is vital for its effective utilization. This training should cover not only the technical aspects but also the benefits and impact of ERP software on their day-to-day tasks. Additionally, ongoing support and assistance must be available to address any challenges or questions that arise.

Data migration and system integration strategies

Migrating existing data to the new ERP system is a critical step in the implementation process. It is crucial to ensure the accuracy and integrity of data during migration. A robust data migration strategy should be in place to map and transfer data from legacy systems to the ERP software seamlessly. Furthermore, considering system integration with other existing software or systems is essential for achieving a unified and efficient workflow.

Continuous evaluation and improvement

ERP implementation is not a one-time event but an ongoing process. Regularly evaluating the performance and effectiveness of the ERP system is crucial for identifying areas of improvement. Collecting feedback from users, monitoring key metrics, and analyzing data can help uncover bottlenecks or areas that require optimization. By continuously evaluating and improving the ERP system, manufacturers can stay ahead of the curve and adapt to changing business needs.

By following these best practices, manufacturers can ensure a successful implementation of ERP Manufacturing Software Solution. Remember that ERP software is not a magic bullet but a powerful tool that, when implemented correctly, can revolutionize your manufacturing operations. In the next section, we will explore real-life case studies of companies that have experienced significant improvements after implementing ERP software. Stay tuned to discover the transformative impact of ERP in the manufacturing industry.

Conclusion

In conclusion, the implementation of an ERP Manufacturing Software Solution has become a game-changer for the manufacturing industry. By streamlining production processes, optimizing inventory management, enhancing supply chain management, ensuring quality control, and providing real-time data analysis, ERP software revolutionizes the way manufacturers operate.

The benefits of implementing ERP software are manifold. Manufacturers can achieve operational excellence, increase productivity, reduce costs, and improve customer satisfaction. With a centralized system that integrates various business processes, manufacturers gain valuable insights and make informed decisions, enabling them to stay competitive in today’s market.

As the manufacturing industry continues to evolve, embracing digital transformation is crucial. ERP Manufacturing Software Solution empowers manufacturers to navigate the complexities of the modern manufacturing landscape. By automating tasks, improving efficiency, and enhancing collaboration, ERP software drives growth and success.

If you’re a manufacturer seeking to optimize your processes, increase profitability, and stay ahead in the market, it’s time to consider implementing an ERP Manufacturing Software Solution. With its comprehensive features, scalability, and customization options, ERP software can be tailored to meet your specific needs.

The future of manufacturing lies in embracing technology and leveraging the power of ERP software. So, take the leap and unlock the potential of ERP Manufacturing Software Solution for your business.

Remember, at erp.vdict.pro, we are committed to providing you with cutting-edge ERP solutions that drive your manufacturing business forward. Contact us today and embark on a transformative journey towards operational excellence.